Brightness Enhancement

WHY WE NEED

Brightness Enhancement

Enhancing brightness for LCD displays is critical for ensuring optimal visibility, contrast, color accuracy, and longevity, ultimately enhancing the user experience and effectiveness of the display in various applications.

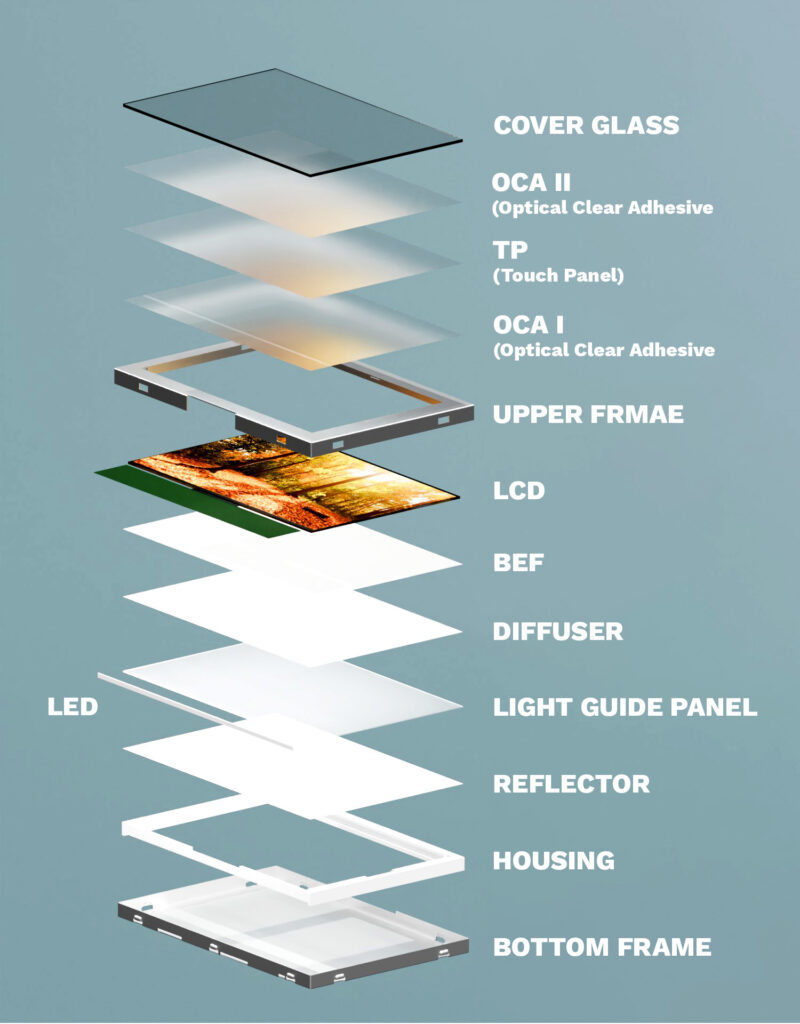

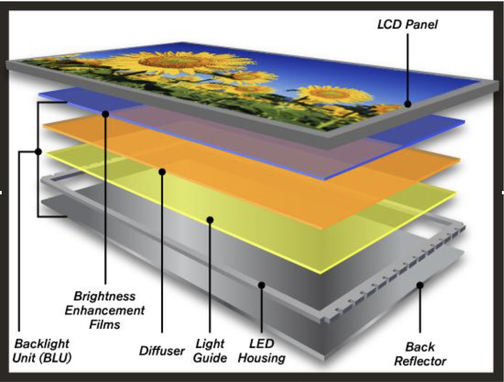

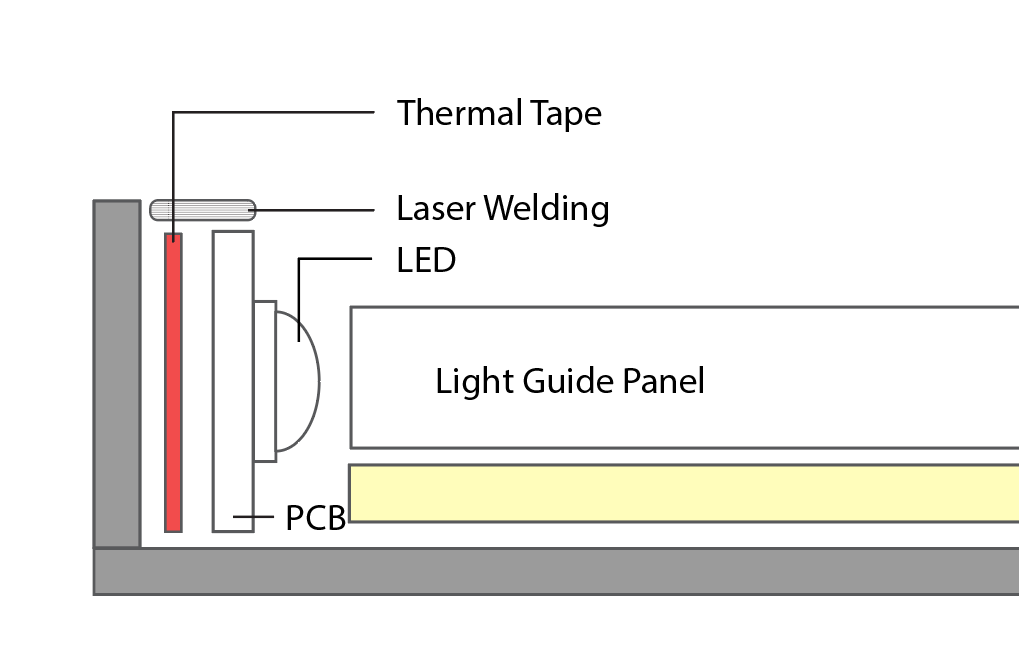

LCM Structure

LGP Module Customization

LED Modification with Heat Dissipation

- LED light strip replacement

| 20-25mA LEDs | 50-70mA LEDs | 100-150mA LEDs | |

|---|---|---|---|

| Brightness | 100% | 120-130% | 150-160% |

- Dual-sided LED light strip

| 20-25mA One Side LEDs | 20-25mA Dual Side LEDs | 50-70mA Dual Side LEDs | 100-150mA Dual Side LEDs | |

|---|---|---|---|---|

| Brightness | 100% | 150-160% | 190-200% | 200-250% |

- Films adjustment and replacement:

Addition or replacement of BEF for brightness enhancement

| No BEF | Add BEF | Add DBEF | |

|---|---|---|---|

| Brightness | 100% | 110-115% | 115-125% |

Heat Dissipation Method:

- Attach thermal tape between the LED light strip and the frame.

- Laser welding prevents the thermal tape from loosening due to temperature changes.

Power Efficient Solutions

The standard LCMs in the market are often designed for limited temperature ranges and low-power LED usage. However, EB-LCM offers the following solutions:

- LED modifications that support a wider temperature range from -40℃ to 85℃.

- Upgrading low-power LEDs (2030 mA/LED) to high-power LEDs (75150 mA/LED), along with power-efficient designs suited for industries like automotive, industrial, aviation, and more.

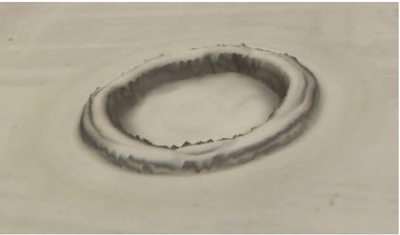

Laser Dotted Technology – Micro-Sized Dotting

Best for high precision, small details, and durable, permanent markings on hard surfaces.

For specimen size of 82 x 28 cm

- EB-LCM Laser Dotted: quantity: 120,000 dots

- Others Laser Dotted: quantity: 80,000 dots

- Silk Screen Printing: quantity: 50,000 dots

Dot Patterns

Crater-shaped dots can enhance brightness by up to 30% more than flat dots produced through silk screen printing.

Why is micro-size better?

- Higher dot density makes the light guide panel significantly brighter.

- Micro-size dots concentrate energy more effectively, resulting in better brightness efficiency.

| Silk Screen Printing | Others Laser Dotted | EB-LCM Laser Dotted | |

|---|---|---|---|

| Dot Size | 0.8-1.0mm | 0.6-0.7mm | 0.2-0.3mm |

| Brightness | 100% | 115% | 130% |

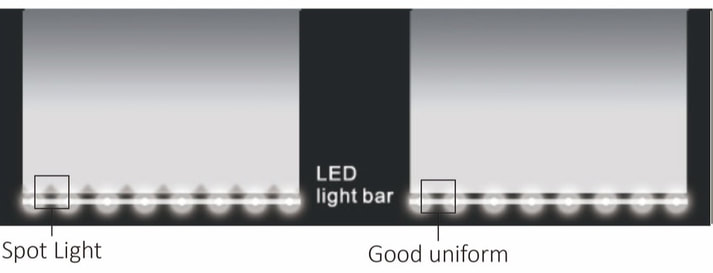

Uniformity

To achieve outdoor legibility on standard LCMs, backlight brightness must exceed 1000 nits when measured at the LCD surface. This typically requires using high-powered LEDs. However, conventional silk-screen printing methods on the lightguide in standard LCMs often result in visible hot spots (or spot lights) due to the LED pitch and high brightness.

EB-LCM addresses this issue by designing and fabricating dotting patterns on the lightguide panel that eliminate hot spots, perfectly aligning with the LED pitch and shape of the LED strip.