LCD Module OEM Services

LCD Scribing

- Capability: Max. Scribing Dimension 92cmx73cm ( 28.7”x36.2”), Tolerance +/- 0.1mm

- Capacity: 180K (Base on 7”, 30 Days)

- Scribe glass cutting service capable for 92cmx73cm as largest

- Liquid Crystal Displays (LCD) substrate.

- The scribe-break is a contamination free cutting method with waterless, heatless and dust-free.

- Scribing is the key of glass cutting process, lateral cracks are prohibited while scribing the median crack for a clear cutting on substrate.

Film Attachment

Soft to Hard

- Capability: 1.5”~43″, tolerance +/-0.1mm

- Polarizer, Explosion-Proof Membrane, Functional Film, OCA on Glass.

- Capacity: 240K (Base on 7”, 30 Days)

OCA Lamination

Hard to Hard

- Capability: Module OCA Lamination (Up to 27”), tolerance +/-0.1mm

- Capacity: 100K (Based on 7”, 30 Days)

Module & T/P Cover Glass Service

A. Machine: Available Size from 2” to 7”

B. Machine: Available Size from 5” to 12”

C. Machine: Available Size from 12” to 27”

Module on hardening cover glass for ball drop test (27″ to 86″), tolerance +/-0.3mm

- Capacity: 10K (Based on Size)

| Maximum Capacity of Each Size | 2" (K) | 7" (K) | 10" (K) | 12" (K) | 27" (K) | 43" (K) | |

|---|---|---|---|---|---|---|---|

| Scribing | 2 lines | 450 | 180 | 180 | 120 | ||

| Film Attachment | 6 lines | 240 | 180 | 150 | |||

| 1 line | 1.2 | ||||||

| COG Bonding | 1 line | 150 | 75 | 60 | |||

| COG + FOG Bonding | 1 line | 300 | 75 | 75 | 60 | ||

| FOG Bonding | 3 lines | 450 | 225 | 225 | 225 | ||

| FOB Bonding | 1 line | 150 | 75 | 75 | 75 | ||

| OCA Lamination (2"~7") | 1 line | 50 | |||||

| OCA Lamination (5"~12") | 1 line | 50 | 50 | 50 | |||

| OCA Lamination (12"~27") | 1 line | 12.5 | 1.2 | ||||

| Station | Glass | Equipment Capability (size) | Equipment Capability (tolerance +/- n) | Manufacturing Capability (actual tolerance +/- n) |

|---|---|---|---|---|

| Scribing | 0.2~1.1 mm | 730*920 mm | ±40μm | ±0.2mm/ ±0.1mm* |

| POL | 0.2~1.1 mm | 1.5"~43" | ±0.1mm | ±0.2mm/ ±0.1mm* |

| OCA | 0.4~2.0 mm | 2"~27" | ±0.1mm | ±0.2mm/ ±0.1mm* |

| COG Bonding | 0.2~2.2 mm | 2"~12.1" | ±5μm (±3δ) | ±6μm |

| COG + FOG Bonding | 0.2~1.1 mm | 2"~12" | ±5μm (±3δ) / ±0.01mm | ±6μm/ ±0.01mm |

| FOG Bonding | 0.2~1.1 mm | 1.5"~15.6" | ±0.02mm | ±0.2mm |

| FOB Bonding | 0.2~1.1 mm | 1.5"~15.6" | ±0.03mm | ±0.03mm |

COG Bonding

- Capability: Chip on Glass (Up to 12.1”), Tolerance +/-6um.

- Capacity : 150K ( Based on 7”, 30 Days)

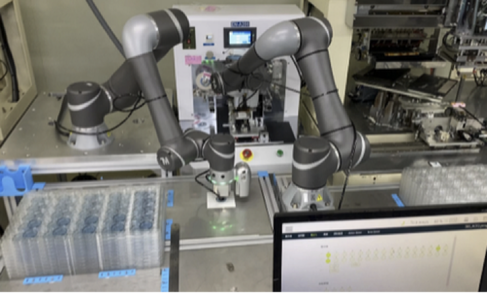

COG + FOG 2-in-1

This two-in-one machine is ideal for monitors used in vehicles, military, or marine, as it meets quality requirements and saves on processing costs. Overall, the Panasonic COG & FOG two-in-one machine is a great solution for LCD OEM.

- Its working area is 12.1″ and is combined with robot and loading/unloading automation.

- The CCD makes the machine fully automatic, reducing errors caused by manual alignment.

FOG Bonding / FOB Bonding

- Capability: FPC on Glass (Up to 15.6”), tolerance +/-0.02mm

- Capacity: 225K (Based on 7”, 30 Days)

ACF Attachment

- Capability: ACF on Glass (Up to 7”), tolerance +/-0.02mm

- Capacity: 45K (Based on 7”, 30 Days)

Backlight Module ODM Services:

Fiber Laser Cutting

- Capability: Max. Cutting Dimension 100*200cm, tolerance +/- 0.5mm

| Gas | Materials | Thickness (mm) |

|---|---|---|

| O₂ | Fe | 10 |

| Cu | 3 | |

| N₂ | Stainless | 4 |

| Al | 3 | |

| Brass | 3 |

Backlight Module ODM Services:

Electric Bending

| Screen Size | Diagonal Length | Bottom Length (cm) | High (cm) | Visible Area (cm^2) | Magnification |

|---|---|---|---|---|---|

| 32 | 81.28 | 70.85 | 39.83 | 2821.99 | 0.5804989 |

| 40 | 101.6 | 88.57 | 49.79 | 4409.36 | 0.9070295 |

| 42 | 106.68 | 92.99 | 52.28 | 4861.32 | 1 |

| 46 | 116.84 | 101.85 | 57.25 | 5831.38 | 1.1995465 |

| 52 | 132.08 | 115.14 | 64.72 | 7451.82 | 1.5328798 |

| 55 | 139.7 | 121.78 | 68.46 | 8336.45 | 1.7148526 |

| 58 | 147.32 | 128.42 | 72.19 | 9270.69 | 1.9070295 |

| 60 | 152.4 | 132.85 | 74.68 | 9921.07 | 2.0408163 |

| 65 | 165.1 | 143.92 | 80.9 | 11643.47 | 2.3951247 |

| 70 | 177.8 | 154.99 | 87.13 | 13503.68 | 2.7777778 |

| 80 | 203.2 | 177.13 | 99.57 | 17637.45 | 3.6281179 |

Backlight Module ODM Services:

Punch Form

- Capability: Max. Punch Dimension 750mmx450mm, Tolerance +/- 0.3mm